Drybase Liquid-Applied DPM

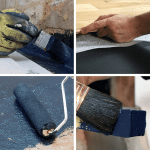

Drybase Liquid-Applied DPM is a one-pack barrier coating that is completely ready to use. It’s available in black or white, and it has a texture comparable to thick emulsion paint. The liquid damp proofing membrane is applied in two applications.

Drybase Liquid DPM hardens to form a flexible and elastic membrane after it has been applied. Drybase Liquid-Applied DPM is a water-based product that may be applied to wet surfaces using a brush, roller, or spray. In an hour or less, the applied DPM is touch-dry.

Drybase liquid-applied DPM forms a barrier against damp, moisture and ground gases (including radon, carbon dioxide, and methane).

Easy to Apply and Ready to Use

Drybase Liquid-Applied DPM is a pre-prepared solution that does not require additional components or ingredients to be mixed in. Simply apply to any clean and laitance-free surface with a paintbrush or roller.

Quick Drying Two Coat Application

A coat of Drybase Liquid-Applied DPM will generally be touch-dry within one hour after it has been applied. This means multiple coats can be applied in a single day to reach the designated material weight.

Ideal Primer for Tile Adhesive Or Screed

As it dries, Drybase Liquid Applied DPM is tacky when applied. If a screed or tiles are to be installed, a final coat can be used as a primer.

Available in 2 Colours – Black or White

Drybase Liquid-Applied Drybase DPM is available in black or white to suit your preferences.

If ordered in black colour, it is dark blue when first applied but turns black when dry so you can see where it is ready for another coat or has become touch-dry.

Reviews

There are no reviews yet.